José Luis Mogollón

Enrique Rodríguez

According to McKinsey [1], «new technologies and ways of working are restoring the performance levels of the top quartile. Our research shows that digital technologies can improve total cash flows by USD 11 per barrel across the offshore oil and gas value chain, adding USD 300 billion a year by 2025.»

If the operational support represents 10-12% of the total cost of a project or operation, the benefits that can produce the introduction of the analytics and the rest of digital transformation tools, only in the offshore hydrocarbons industry, can reach the order of 25 billion dollars for that year.

Currently, the term in vogue in advanced companies is Digital Transformation, the use of digital techniques with the optimization of processes to provide value and sustainability over time. Specifically, and for illustrative purposes, the expectation is that automation and digitization will produce savings of the order of $100 billion annually in the upstream exploration and production (E&P) of the hydrocarbon production industry (O&G). This represents 10% of the annual total in Opex and Capex of this industry [2]. Similar substantial savings are expected in industries of all types of energy.

Within the supports of Digital Transformation are robotic and intelligent automation, the Internet of Things or IoT, artificial intelligence, big data and augmented reality.

The Digital Transformation involves important cultural changes, such as the dismantling of organizational silos and resistance to change, a product of both the fear of losing importance in the organization, and the education received from the organization itself that ‘things when they work are not touched’.

One area where this fact is revealed is in the Operational Support, defined as the set of activities that support the execution of the operation or project, such as maintenance, relationship with suppliers and contractors, documentation of processes, internal logistics, management of disruptive events and nonconformities in general and compliance management, among others.

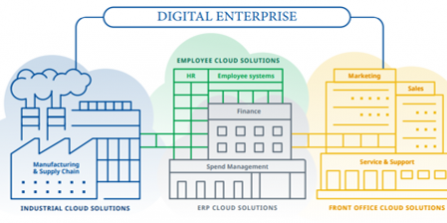

The Yokogawa company’s model [3], shown in the following figure, outlines the Digital Transformation, both in conventional manufacturing as well as in the development and operation of power generation, from hydrocarbon fields, wind farms, nuclear power plants, to the interconnected electricity transmission network on a local and regional scale.

Within this vision of the digital enterprise appears two fundamental elements, the Service and the Support. These components, although complementary to key operations such as production itself and its operational management, are often critical. It is known that in these areas there are multiple problems such as:

- Late or incomplete communication between executors, support companies and project owners

- Lack of early detection of performance issues

- Failures in the quality control of execution of different stages and their milestones

- Delays in the approval processes, both by the client, as by the responsible executor, and by third parties that support the execution.

- Lack or multiplicity of materials and equipment with inappropriate distribution, resulting in some sites not being able to provide the necessary resources to complete the programme of work on time.

- Traceability of decisions reception and information sending.

- Loss of information and knowledge both due to lack of proper storage and non-availability at the right time

- Lack of images and videos in real time in the face of conflicting situations such as deterioration of wiring or unexpected material failures

- Existence of multiple formats for information gathering, tabulation, graphing and reporting.

- Cumbersome and unnecessarily redundant processes of monitoring the execution and its documentation.